Pipeline installations: What Is Horizontal Directional Drilling?

Theory, Practical Information and Tips

Horizontal Directional Drilling or HDD, is a steerable trenchless method of installing underground pipe, conduit, or cable in a shallow arc along a prescribed bore path by using a surface-launched drilling rig, with minimal impact on the surrounding area.

Directional Drilling is used when trenching or excavating is not practical. It is suitable for a variety of soil conditions and jobs including road, landscape and river crossings. Pipe can be made of materials such as PVC, polyethylene, polypropylene, ductile iron, and steel as long as it can be pulled through the drilled hole.

When to Consider Trenchless Technology?

You should consider Trenchless Technology, if you answer with a YES to two or more of the below questions:

- Is the pipe 5 ft (1.5 m) deep or more?

- Is the pipe below water table?

- Is the soil unstable?

- Is the underground congested with other utilities?

- Is the installation in an urban area?

- Is the installation under a roadway, railroad or river?

- Is the installation in a residential area?

- Are installation lengths over 180 ft (60 m)?

Trenchless Technology Advantages Over Traditional Methods

- Underground installation of utilities, with minimum surface disruption.

- Costs relatively lower with greater installation depth.

- Deeper installation = less chance of damaging existing underground utilities.

- Less equipment, manpower and fuel needed per meter of installation.

- Lower surface restoration costs and economical costs caused by road closures.

Vermeer

Dealers & locations

- United Arab Emirates ›

- Kingdom of Saudi Arabia ›

- State of Qatar ›

- State of Kuwait ›

- Sultanate of Oman ›

- Kingdom of Bahrain ›

- Iraq ›

- Full list of countries ›

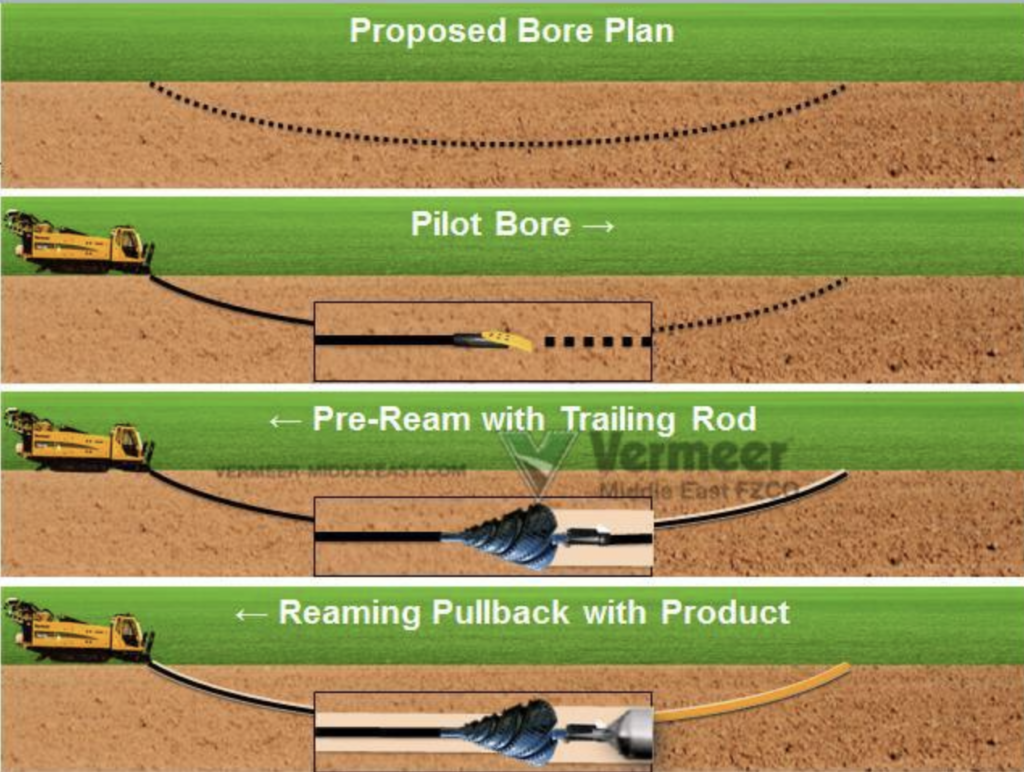

Techniques / HDD Stages

A drill head can enter the soil from ground level, be manipulated to follow a planned bore path and return to the surface at a distance from the entry point. A reamer and the product to be installed are pulled back through the bore path to the initial entry point. See the following image to illustrate different horizontal directional drilling techniques.

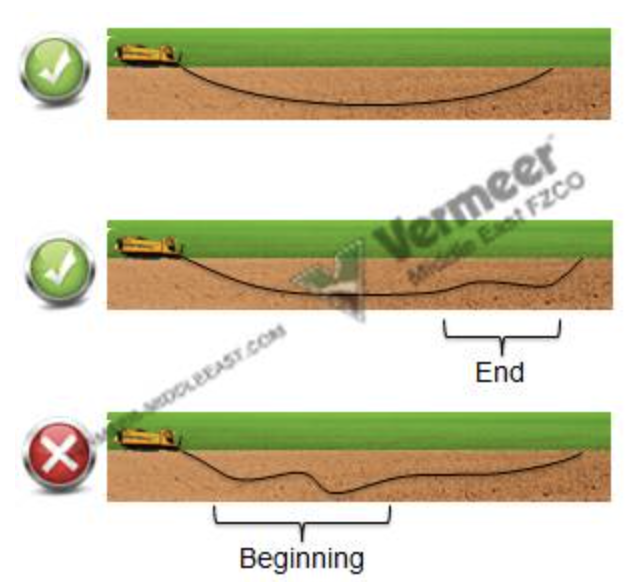

How To Set Up Your Rig

Maneuver the machine into the correct location according to the setback calculations provided in the bore planning stage. Lower the rack pad to the ground and adjust the rear outrigger to the desired position while referring to the locating system to achieve the desired entry pitch.